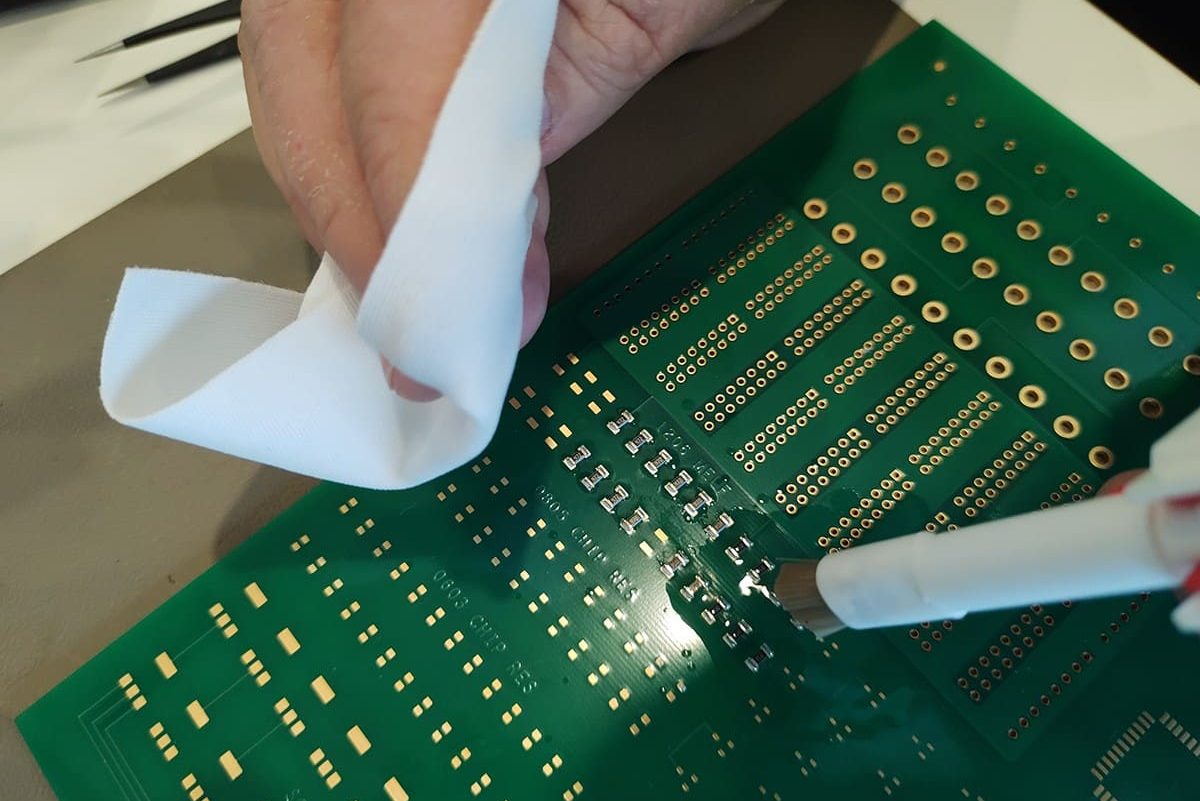

When you are cleaning printed circuit boards, there is a process you have to follow. Wetting, scrubbing, rinsing, and drying are the steps involved here. Unfortunately, a lot of people overlook the importance of the last one. If you want to improve the longevity of your device, you should focus on drying as much as you pay attention to the first three steps.

If there is residual moisture on the surface, you will face various problems in the future. This includes everything from dendrite growth to electrochemical migration to board delamination to component corrosion. On top of that, it might also outgas as you solder, create blowholes, and prevent coating adhesion during conformal coating.

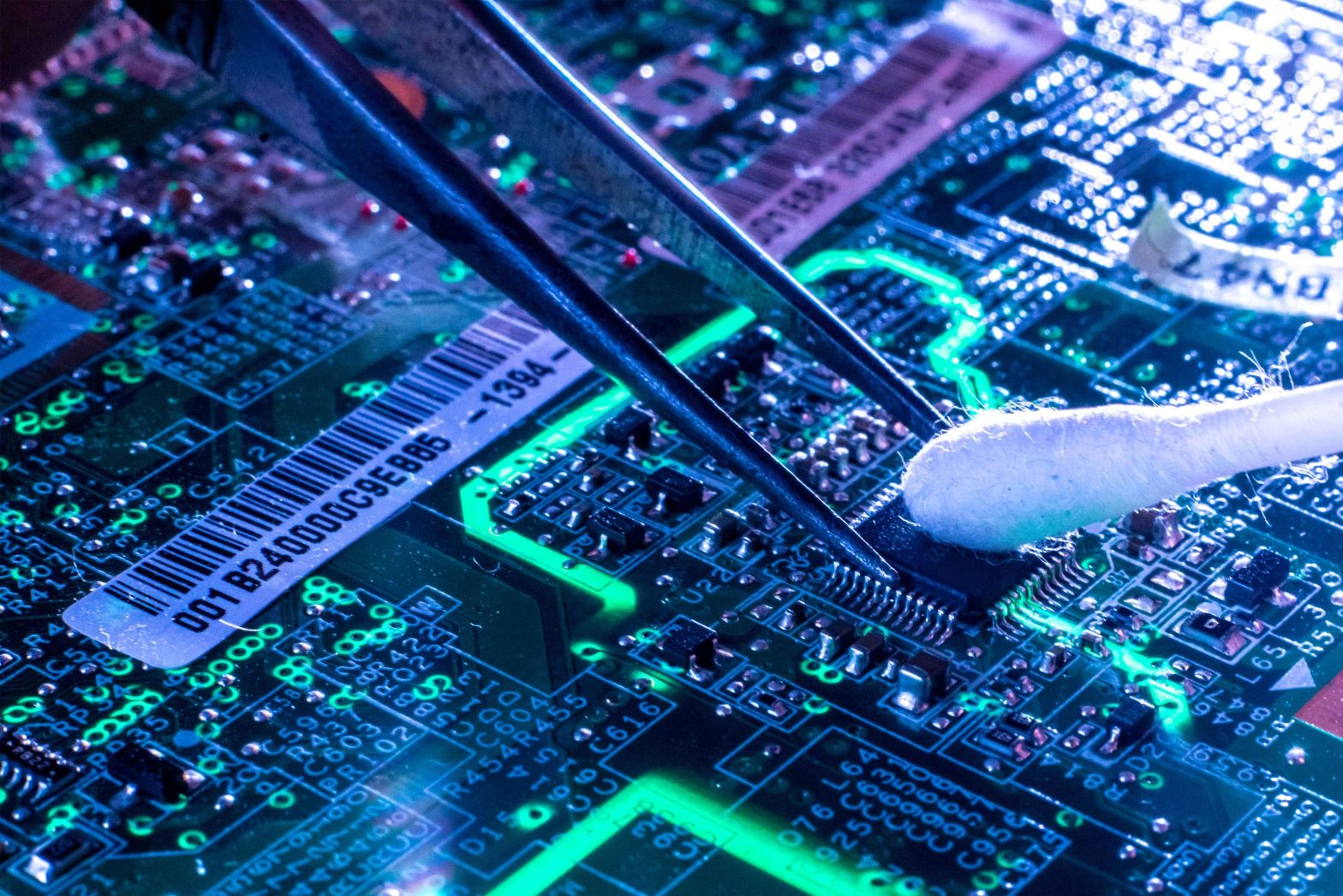

Those found inside wearable medical devices are densely populated to ensure that they are lighter, smaller, and less invasive. They are also more comfortable and discreet when patients have to wear them. However, PCBs are now densely populated with various bottom termination components such as quad-flat no-leads and grid arrays. Their tight standoff heights can result in trapped moisture, which can complicate the drying process.

Modern medical devices made to be worn come with delicate parts made with different materials. Lightweight metals and softer plastics can be damaged easily. If you want to prevent this from happening, you have to clean and dry these components carefully.

You can dry PCBs using different methods and approaches. Typically, the right choice will depend on the employed cleaning used. Most of the time, drying is done with the help of air, heat, vapor, compressed gas or wipes. Some of them can be used together to get the best possible results. You can do it yourself if you have the technical know-how or hire experts to take care of the cleaning and drying for you.